MANUFACTURING FACILITY

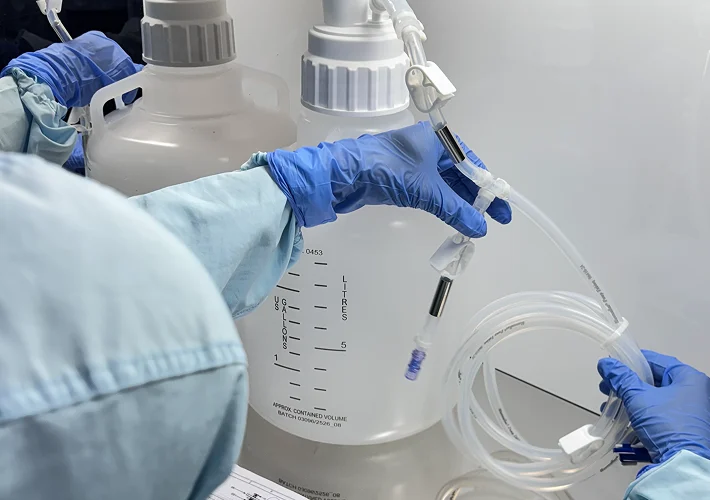

World-Class Controlled Environment for Precision Manufacturing. Welcome to the BioMax Class 7 Cleanroom, a state-of-the-art controlled environment designed to meet the highest standards of contamination control and compliance for critical scientific and manufacturing applications. Our facility combines Grade C manufacturing & Grade B components assembly infrastructure with expert processes to support biotechnology, pharmaceutical, medical device, and advanced research operations.

OUR CLEANROOM IN ACTION

ADVANCED CLEANROOM CAPABILITIES

Our systems and protocols reflect global cleanroom standards and are supported by rigorous quality controls, ensuring

that processes conducted within the cleanroom meet your strict requirements.

ISO-classified spaces tailored for applications requiring defined air cleanliness levels and controlled environmental conditions.

Precision-controlled airflow systems, including HEPA-filtered circulation, to minimize particulate contamination.

Dedicated gowning and airlock zones to ensure contamination prevention before accessing critical workspaces.

Flexible layout optimized for custom assembly, sterile production, sampling, or sensitive testing workflows.

IN-HOUSE GAMMA STERILIZATION

Setting a New Standard in Biopharma Manufacturing

IN-HOUSE GAMMA STERILIZATION

ISO-CERTIFIED CLEAN ROOMS & USP CLASS VI MATERIALS

CUTTING-EDGE APPLICATION LAB & LOT TRACEABILITY

COMPREHENSIVE PRODUCT TESTING & VALIDATION SERVICES

With state-of-the-art facilities in both India and Germany, we’re committed to delivering quality, consistency, and innovation on a global scale. Partner with us to elevate your biopharma success

See How it Works

PURPOSE-BUILT FOR QUALITY & COMPLIANCE

The BioMax Cleanroom is more than just space — it’s a capability hub designed for With precise environmental regulation and robust operational procedures, our cleanroom supports reproducible outcomes and regulatory readiness.