Bioprocess solutions are specialized systems—such as single-use assemblies, media bottles, and fluid transfer setups—that enable the safe, sterile, and scalable production of biological products. They play a vital role in biotechnology, pharmaceuticals, and diagnostics by ensuring process integrity, reducing contamination risks, and allowing laboratories to customize setups according to their experimental needs. Bioprocess solutions help scientists turn concepts into quantifiable outcomes, from growing cells and creating vaccines to enabling innovative treatments.

Single-use assemblies, which provide greater flexibility, sterility and efficiency, have replaced conventional reusable systems in bioprocessing over time. BioMax® bioprocess solution are manufactured to meet the particular requirements of every laboratory rather than using a rigid, one-size-fits-all approach.. Making the correct decision is crucial because of the adaptability.

Why Choosing the Right Bioprocess Solution Matters

There are requirements specific to each lab experiment. For vaccine research, a setup that is ideal for cell culture might not be appropriate, and visa versa. Workflows stay effective, results are dependable, and compliance requirements are satisfied when the appropriate bioprocess solution is chosen.

Choosing the wrong bioprocess solution can lead to reduced yields, contamination risks, and compliance challenges, all of which increase costs and delay research. To avoid these issues, many labs rely on single-use, configurable systems that are tailored to specific workflows, ensuring reliable results and efficient operations.

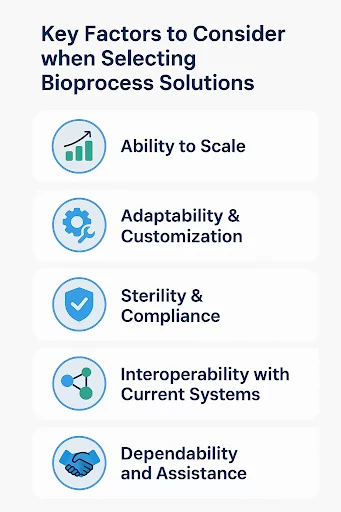

Key Factors to Consider when Selecting Bioprocess Solutions

1. Ability to Scale

A solution that is flexible enough to be used in pilot studies and can eventually be adaptable for full-scale production if it proves effective in small-scale research. Selecting systems that scale easily guarantees seamless transitions without requiring a complete investment in new configurations.

2. Adaptability & Customization

Not all laboratories function in the same manner. Workflow based changes are possible with customizable solutions, like the ones offered by Accumax. Media bottles, for instance, can be made with several ports, and placement & numbers of these ports can be changed to accommodate experimental flow. This degree of flexibility and adaptability aids labs in meeting highly specific research goals, reducing waste, and increasing efficiency.

3. Sterility & Compliance

Sterile products are very important in bioprocess. Labs can more easily comply with international regulatory standards when they use solutions that facilitate gamma sterilization and contamination-free handling.

4. Interoperability with Current Systems

In order to save time when adjusting procedures or resolving discrepancies, bioprocess assemblies should integrate seamlessly with current lab equipment. Additionally, compatibility guarantees that scientists can concentrate on their work rather than on system constraints.

5. Dependability and Assistance

Long-term confidence is more important than merely purchasing equipment. Selecting a partner who has and provides technical know-how, post-purchase support, and reliable product quality ensures that outcomes stay precise and repeatable.

Customization: The Accumax Advantage

Every experiment has a different workflow. Accumax has created the Biomax Bioprocess Solution – Single Use Assemblies in recognition of this, enabling researchers to customize systems to meet their exact specifications.

Some of the standout customisation options are :

- Configurable Containers: Depending on how the fluids in your experiment must flow, you can alter the type of container and also the number & location of ports.

- Flexible Assemblies: Single-use assemblies parts can be chosen and put together to precisely match process requirements, which lowers the possibility of mistakes and saves important time.

- Broad Range of Applications: These assemblies easily adapt to both simple lab-scale work and complex research environments.

Instead of making experiments fit into strict, pre-made frameworks, this flexibility allows labs to set up systems that actually work for them.

How the Right Partner Makes a Difference

Picking the right partner in bioprocessing goes beyond just buying products—it’s about teaming up with people who get your struggles, back your aims, and always deliver dependable and groundbreaking solutions.

This is how Accumax sets itself apart. With years of experience in lab and bioprocess solutions, Accumax combines premium grade setup, regulatory expertise, and customer-focused teamwork to make sure every process runs without a hitch.

We pledge to help you succeed by offering:

- State-of-the-art manufacturing facilities to ensure consistent global standards.

- Our in-house Gamma Sterilization Facility to boost safety, cleanliness, and supply chain oversight.

- Help with regulatory and technical certificates such as test reports, spec checks, and open audits, etc.

- Custom single-use assemblies setups made to fit specific jobs with quick tweaking help.

- Full batch tracking and strict quality checks ensure complete process reliability.

- Flexible and matching solutions with industry-best delivery times.

When you team up with Accumax, you get more than a product—you get a committed partner dedicated to boosting your bioprocess journey through top-notch quality, new ideas, and reliability.

Why Accumax?

How Does It Begin?

Step 1: Custom Design for Your Application

It all starts with a design created exclusively for your bioprocess requirements. From tubing, fittings, and closures to filters, sensors, and bottles—every detail of the assembly is carefully customized to meet your exact application.

Step 2: Component Selection & Detailed Drawings

Every component is precisely documented in a comprehensive drawing, serving as a clear blueprint of your assembly. Before production, this drawing is shared with you for review and approval. Each is assigned a unique reference number for traceability and quality assurance.

Step 3: Production in ISO-Certified Cleanrooms

Once approved, your Single Use Assemblies are manufactured and packaged in our advanced ISO-certified cleanroom facilities, ensuring uncompromising sterility, consistency, and quality control at every stage.

Applications of Bioprocess Solutions

Applications for bioprocess solutions are numerous and include :

- Biotechnology Research: Supporting molecular research, protein expression, and cell culture.

- Pharmaceutical Development: From finding new drugs to creating vaccines.

- Clinical Diagnostics: Making sure that labs handle sensitive samples run smoothly.

- Regenerative Medicine and Cell Therapy: Providing sterile, adaptable systems for advanced treatments.

- Industrial Bioprocessing: Enabling consistent, high-volume production without sacrificing quality.

Single-use assemblies’ versatility speeds up discovery in each of these domains while preserving sterility and compliance.

Conclusion

Solutions for bioprocesses are not universally applicable. The ideal system should scale with your research, adjust to your workflow, and satisfy strict compliance standards.

Accumax offers scientists adaptable, dependable, and effective instruments with its Biomax Bioprocess Solution – Single Use Assemblies that guarantee experiments go smoothly from beginning to end. It is more than just a product; it is a collaboration that helps labs remain future-ready by fusing flexibility and precision engineering.