Labs around the world change fast. As scientists need to work quicker, keep things sterile, and adapt, picking the right lab gear matters more than ever. In the past, labs used systems they could clean and use again. These were tough and reliable, but took a lot of time to clean. Now, Single Use Assemblies are setting new trends. They’re handy, trustworthy, and help scientists work faster.

So why do modern labs often pick single use assemblies, and how do they stack up against the old systems? Let’s take a closer look.

What Are Single Use Assemblies?

Single use assemblies are lab components you can use just once. They come sterile in a ready to use packaging, with all the parts you need – connectors, tubes, bottles, and closures. These assemblies help keep things sterile and consistent from beginning to end.

Accumax has a full line of BioMax Single Use Assembly products, including:

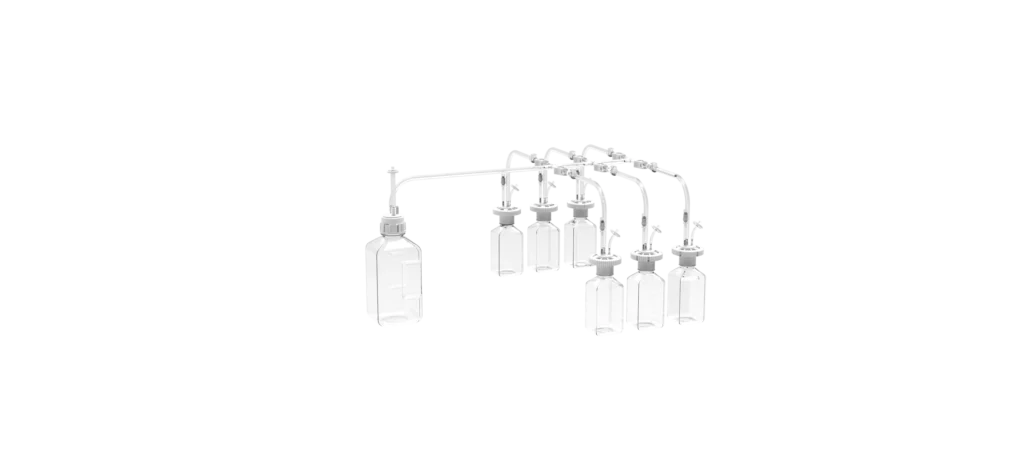

- BioMax Carboys – made to store and move large amounts of liquid.

- BioMax Media Bottles – keep culture media sterile and secure during handling.

- BioMax Erlenmeyer Flasks – great for growing cells, mixing stuff, and incubating.

- BioMax Heavy Duty Reagent Bottles – built to handle tough lab conditions.

- BioMax VentiPort & Aseptic Closures – allow transfers without contamination.

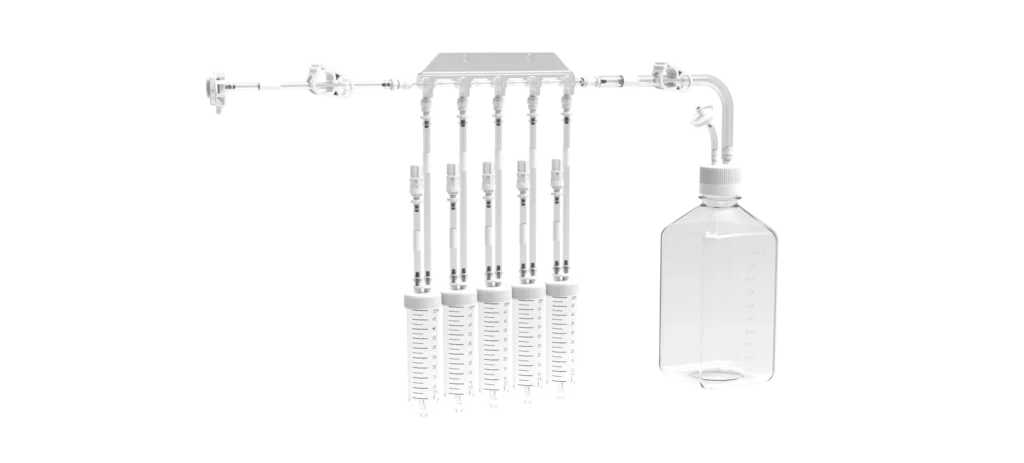

- BioMax Centrifuge Tubes & Bottles – store and separate samples.

- and much more

The careful design of each product aims to reduce the risk of contamination and make them easy to use. This helps labs keep their work consistent and reliable.

Traditional Systems: A Well-Known Approach

Before single use technologies became popular, traditional glass and steel systems dominated labs. These tough and reusable tools have helped labs for many years. However, their use often involves:

- Cleaning after each experiment.

- Sterilizing through autoclaves or chemical treatments.

- Checking for safety before using again.

While reliable, these steps make daily lab work more complicated and time taking which could be utilised in some other task.

Why Labs Are Moving to BioMax Single Use Assemblies

1. Easy to Use

BioMax Single Use Assemblies help labs save a lot of preparation time. Because these assemblies come in clean and ready to use packaging, scientists can jump right into their experiments instead of worrying about the equipment’s sterility.

Result: Scientists spend more time on research and less on equipment up-keep.

2. Dependable Sterility and Uniformity

Modern research needs uniformity. Single use assemblies are produced in controlled environments and sterilized to ensure the highest levels of reliability. This cuts out the chance of differences caused by cleaning techniques or how people handle things.

Result: Scientists feel more sure about their findings and can repeat their data.

3. Better Turnaround

Old systems need cleaning and sterilizing between uses, which causes delays. But single use assemblies are ready to go right away. This lets labs do more experiments in less time.

Result: Work moves faster without cutting corners on quality.

4. Flexibility to Meet Changing Lab Needs

From tiny research labs to massive biopharma facilities, Single use assembly adaptability makes them fit for various scales. Whether you need bottles to store media flasks to grow cultures, or closures to transfer sterile materials, single use assemblies adjust to changing protocols without a hitch.

Result: A solution that expands as your lab’s needs grow.

Single Use Assemblies vs. Traditional Systems: A Clear Edge

| Factor | Single Use Assemblies | Traditional Systems |

| Setup Time | Pre-sterilized, ready to use | Requires preparation and cleaning |

| Sterility Assurance | Consistent and validated | Dependent on cleaning accuracy |

| Turnaround Speed | Faster workflows | Slower due to sterilization |

| Flexibility | Scalable and adaptable | Best for fixed, repetitive use |

Why BioMax Single Use Assemblies?

At Accumax, we understand that sterility, safety, and compliance are critical in every bioprocess. That’s why BioMax Single Use Assemblies are designed to deliver reliability from the ground up:

- BioMax Single Use Assemblies are manufactured under ISO 9001:2015 and ISO 13485:2016 certified systems

- They are made from animal-origin-free and latex-free materials, meeting EC 999/2001, EMEA/410/01, and FDA 21 CFR standards

- Each assembly is gamma-irradiated in our in-house gamma sterilization facility and validated to ISO 11137, achieving a sterility assurance level (SAL) of 10⁻⁶.

- Biological safety is proven through USP Class VI (Chapters <87> and <88>), confirming that the materials are non-toxic in both in vitro and in vivo testing.

- Endotoxin, DNase, and RNase testing are conducted in our in-house laboratory for enhanced reliability and assurance, validated per ISO 11737 and USP 85.

- Every batch undergoes subvisible particle analysis in compliance with USP <788>

- Assemblies are tested for extractables and leachables in accordance with USP <665> and BPOG guidelines

- Manufacturing is carried out in a Grade B cleanroom, compliant with ISO 14644-1

If you’re a distributor backing customers or a scientist pushing research forward, the BioMax line gives labs the power to get results they can trust.

Application of Single-Use Assemblies

The life sciences industry relies on single-use assemblies in many precise processes where avoiding contamination is essential. Accumax BioMax systems help protect product quality, simplify processes, and meet strict requirements in key applications.

- Sterile Drug Product Manufacturing

BioMax Carboys, Media Bottles, and Aseptic Closures help store delicate formulations to lower the chances of contamination. They help keep patients safe and maintain the quality of critical drug products.

Biopharmaceutical Manufacturing

BioMax Erlenmeyer Flasks and Heavy-Duty Reagent Bottles support both upstream and downstream activities in production. They offer dependable results for tasks like cell culture preparing media and storing reagents. This dependability helps speed up schedules and keeps processes stable.

Aseptic Fill-Finish Operations BioMax VentiPort & Aseptic Closures keep products sterile during fill-finish workflows. This helps protect the quality of biologics and vaccines while meeting strict regulatory requirements. It also builds trust in the final doses provided.

- Critical Process Filtration

BioMax Centrifuge Tubes and Bottles provide safe and contamination-free handling for filtration workflows. Their reliable design ensures accurate and consistent results playing a key role in achieving quality in important bioprocessing tasks.

Wrapping Up

The decision between sterile disposable assemblies and conventional systems boils down to productivity, cleanliness, and flexibility. While conventional systems have a rich history, disposable assemblies match up better with what modern labs need today—where time, accuracy, and trustworthiness matter most.

Accumax’s BioMax Single Use Assemblies help labs boost their productivity, protect their findings, and get ready for future challenges.